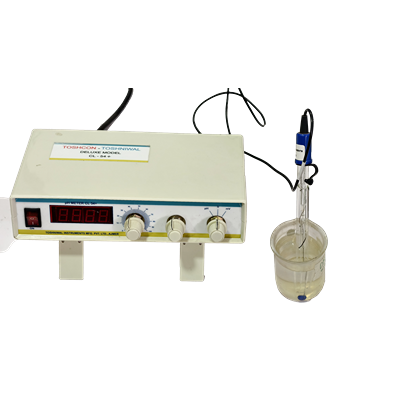

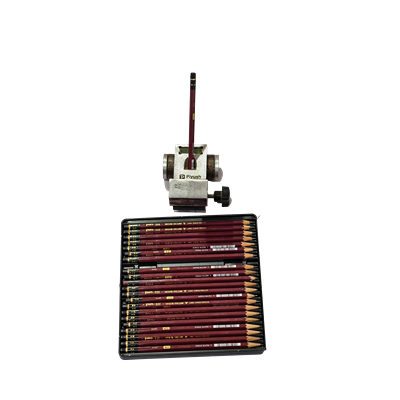

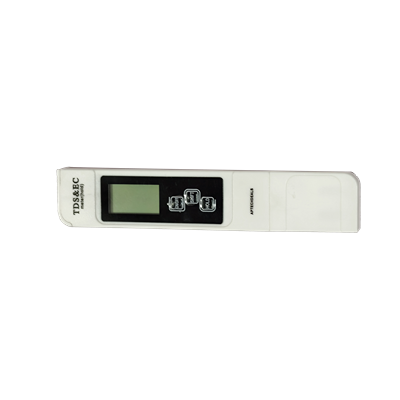

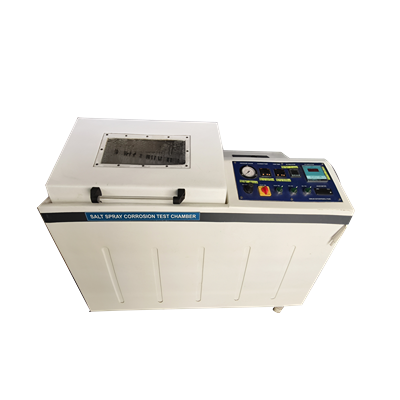

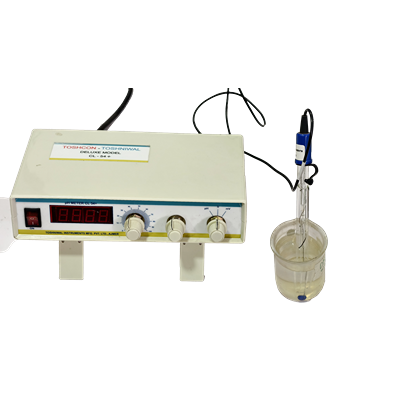

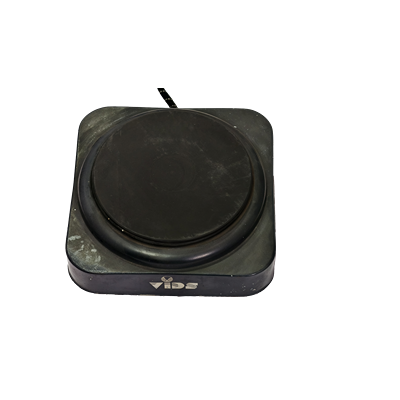

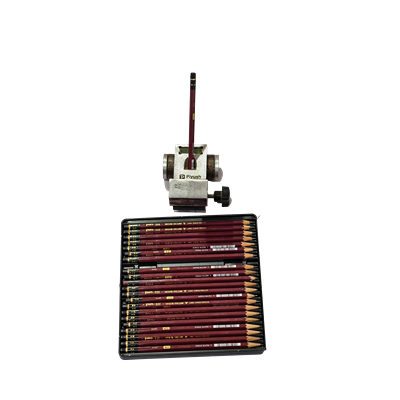

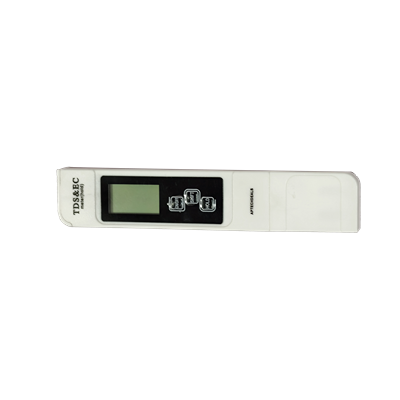

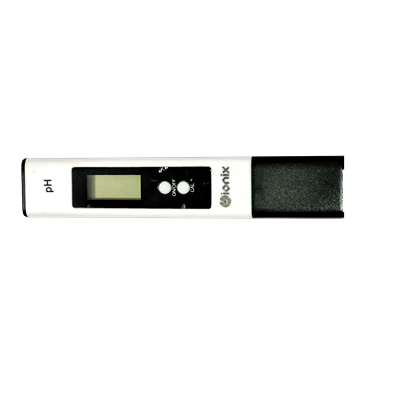

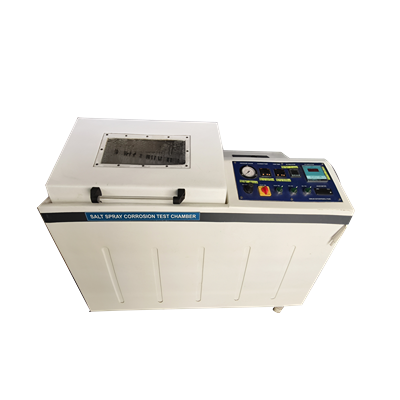

Lab Instrument

The coating provides robust protection against a wide range of chemical and environmental exposures. It ensures long-lasting durability and performance under contact with acids, alkalis, fuels, oils, grease, and water.